| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | CTCP-AP |

| Model Number : | SCMT09T3/SCMT1204 |

| Certification : | ISO9001:2008 |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability : | 300000 pieces per month |

| Delivery Time : | Stock items can be sent within 3-5 days |

SCMT1204 Series Tungsten Carbide Inserts , Cemented Carbide Cutting

Tools

About Carbide turning inserts:

Turning inserts employ highly engineered composite

structures,coatings and geometry features to achieve great accuracy

and high material removal rates .

The benefits of using replaceable inserts for turning tools

include:

Some inserts can be indexed to use other edges when one becomes

worn

Inserts are quickly and easily replaced at the machine.

Models introduction:

Grades recommendation:

YC330 | For finish machining of steel at high speed | CVD coating |

YC331 | The most versatility grade of steel processing | CVD coating |

YC332 | For rough machining of steel parts | CVD coating |

Size and Chipbreaker details of SCMT series list :

| HF | HM |

| SCMT09T304 | SCMT09T304 |

| SCMT09T308 | |

| SCMT120404 | |

| SCMT120408 |

Our inserts advantage:

1> Secure insert grade means you get a reliable and secure performance every time.

2> Long tool life means you get higher machine utilization and higher production.

3> Less tool breakage means you can control costs and reduce the cost per component to increase profits.

WHY CHOOSE US ?

01: Strict QC system :

We have full set production line and strict quality management system .

02:Professional team :

We have professional engineer team and produce team ,sales team can provide comprehensive one-stop service for you .

03:Competitive price :

Factory directly ,we can provide our best price to support you .

04:Fast delivery time :

Standard item we usually have large quantity stock.We have big production capacity to guarantee fast delivery and on-time shipment .

Customer’s case: when a insert is failed on performance:

1. Flank Wear

-Workpiece material contains high hardness chemical elements (tool

steel, die steel)

Increase cutting speed if abnormal flank wear is caused by a very

slow cutting speed.

Solution: Reduce cutting speed or feed rate or use more wear

resistant grade

2. Crater Wear

-Workpiece material contains high hardness chemical elements

Solution: Reduce cutting speed or feed rate or use more wear

resistant grade

3. Cracking

-Excessive feed rates when interrupted cutting

Solution : Reduce feed rate, Use tougher grade

Quality control:

Technical support and after-sale service:

1.Suitable processing parameteres can be provided for our customer

.

1:Suitable processing parameteres can be provided for our customer

.

2:According to the workpiece design, material and CNC machine feed

rate, cutting speed we can recommending a full set of practical

scheme.

3:Suggsting more suitable model to replace the brands of Japan,

Korea and so on.

4. We also supply matching tool holders which can help you saving

time and cost of purchasing.

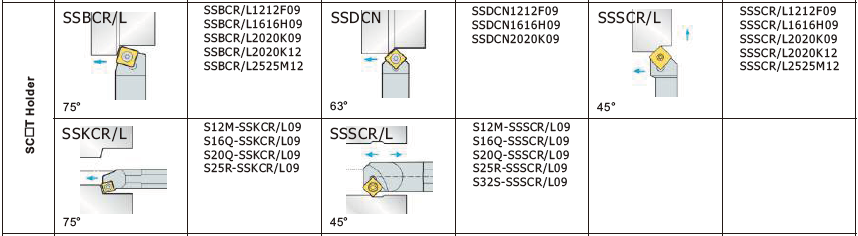

SCMT Series holder specification for your reference :

Thanks for your support to Apple carbide ,welcome to contact us for

more details !

|