| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | CTCP-AP |

| Model Number : | APMT1135 |

| Certification : | ISO9001 |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability : | 300000 pieces per month |

| Delivery Time : | Stock items can be sent within 3-5 days |

Metal Working Good Processing Tungsten Carbide Inserts APMT1135 Carbide Milling Tips

What is tungsten carbide inserts?

Cemented carbides are composed of a metal matrix composite where carbide particles act as the aggregate and a metallic binder serves as the matrix. The process of combining the carbide particles with the binder is referred to as sintering.

Excellent chip control for workpiece:

Items introduction:

| H | M | XM |

| APMT1135PDER-H | APMT1135PDER-M | APMT1135PDER-XM |

| APMT1604PDER-H | APMT1604PDER-M | APMT1604PDER-XM |

Different chipbreakers:

Grades recommendation:

| YP730 | For finishing and semi finishing of stainless steel and high temperature alloy. | PVD coating |

| YP731 | It's universal and suitable for the processing of stainless steel and high temperature alloy. | PVD coating |

Contrast Advantage/Benefits of choosing our carbide inserts:

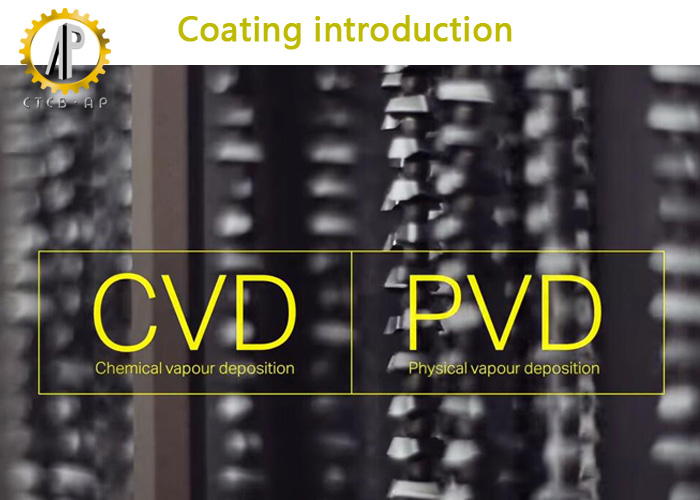

1. High wear resistance with PVD coating.

Most coatings generally increase a tool's hardness and/or lubricity. A coating allows the cutting edge of a tool to cleanly pass through the material without having the material gall or stick to it.

2. High hardness and wear resistance.

The basic characteristics of cemented carbide are high hardness and wear resistance, especially high temperature hardness.

3. Improve Production efficiency.

Long tool life means you need less time changing the inserts while

machining. A reliable and safe performance every time.

4. Less tool breakage, cost down of each component

Saving costs and reducing the cost of each component to increase the profits .The high wear resistance makes the long tool life of the carbide inserts, which means you could saving more budget on purchasing the inserts.

Customer’s case: when a insert is failed on performance:

1. Flank Wear

-Workpiece material contains high hardness chemical elements (tool

steel, die steel)

Increase cutting speed if abnormal flank wear is caused by a very

slow cutting speed.

Solution: Reduce cutting speed or feed rate or use more wear

resistant grade

2. Crater Wear

-Workpiece material contains high hardness chemical elements

Solution: Reduce cutting speed or feed rate or use more wear

resistant grade

3. Cracking

-Excessive feed rates when interrupted cutting

Solution: Reduce feed rate, Use tougher grade

Quality control:

Technical support and after-sale service:

Our company can providing the following technical service for customers:

1: We are professional production factory.

2: 10 years production experience in tungsten carbide field.

3: 100% virgin raw material.

4: 100% inspection before shipment to make sure qualified products and no more or less than order.

5: Quality control and delivery time is strictly controlled.

6: Flexible payment terms, T/T, L/C, West Union and so on.

The coating is usually deposited via thermal CVD and, for certain applications, with the mechanical PVD method at lower temperatures.

Tool Holder:

|